NANOPASTE: SPECIAL COATING PROCESS

NANOPASTE: SPECIAL COATING PROCESS

Our unique technology can coat almost any flat surface with a special paste through a modified printing process. With our special coating process, we make flat surfaces heat, cool, glow or darken completely without the use of limited raw materials such as rare earths.

We do not use rare

earths and metals.

Our technology opens up

new possibilities.

Usable for everything

from house to smartphone.

There are almost no limits to the possible applications. This means that all the products listed above have already been approved as products. From the large number of products already developed, the following areas have been certified and approved for the market so far:

- Electricity storage technology

- Heating

- Power generation

- Air conditioning

- Lighting

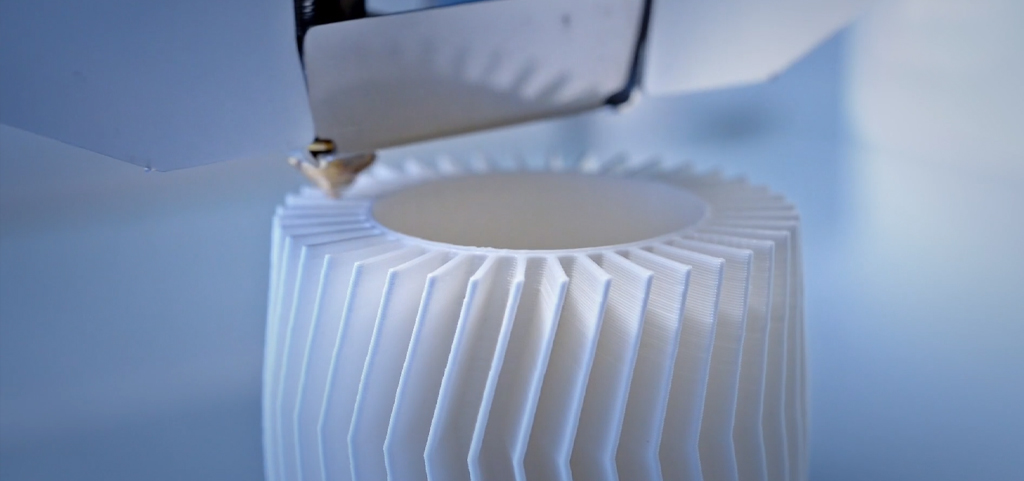

The production process

In the test facility, a sample product is manufactured and tested manually. Then the production line is set up and loaded. In a kind of printing process, a special printing paste is applied to a carrier material. 4 plant modules make up the production plant.

Each module is equipped with a crane robot and a separate drying chamber. The end products then leave the plant in a 15-second rhythm, i.e.: 240 pieces per hour or over 5,000 pieces in a day’s production. All necessary connections are “printed” onto the bodies during the application process.

Advantages of the coating technology

(1) High production yield, wide range of applications

Fully automatic process, coating possible on almost all flat surfaces.

(2) CO2-neutral production

The CO2 emission is climate neutral, no environmental pollution!

(3) High availability

The innovative plant technology is controlled and operated fully automatically.

It is self-cleaning

(4) Continuous operation

The systems are verifiably running 24/7

(5) Safety

Complete monitoring of all technical processes

(6) Planning reliability

Unproblematic conversion of the plant to other production goods, e.g. – electricity storage technology

Power generation

- Air conditioning

- Lighting

- Heating

(7) Clear production process

Simple structural requirements, easy operation of the plant.

Fully automatic production process, only the loading and setting up of the plant and the packaging of the produced goods is done manually.

(8) Expansion of new technologies and products

Every company we serve as a cooperation partner will benefit from the further development of new products.

(9) Space-saving production site

The required production hall only needs an area of 20m x 10m, plus office, storage and sanitary rooms.

Leave A Comment

You must be logged in to post a comment.